Engineering Change Management

The business processes from the design of a new product to the series-production get more and

more complex. Simultaneously the number of employees that are involved in the planning process,

manufacturing organization, quality assurance and so on is increasing. The management

of changes on the product or process gets more extensive. The module iQ-ECM represents

the manifold and often not exactly defined buisness processes and all out of this resulting effects

and measures.

The Engineering Change Management has a comprehensive responsibility. For example the following departments and sectors are involved:

|

|

General EC workflow

Typical ECs, that have to be processed by several departments:

- New construction of a part

- Changing measure for a new version

- Process improvement

- New logistical work flow

- Temporarily accepted special release

Several meetings, measures, releases etc. are required until the change can be launched finally.

iQ-ECM in conjunction with iQ-Projekte is so flexible designed, that a great variety of company specific work flows can be represented.

Two phases are distinguished:

- Evaluation phase: A request for a change (made by the customer, supplier or own plant) is evaluated by different departments, priced and accepted or refused.

- Implementation phase; the accepted EC has to be realized. All preparations (informing the supplier, rebuilding the production line, new PPAP for the customer etc) have to be made. The date of the changeover is set.

EC master file

- Registration of the suggestion for change

- EC-Key from number range or external guidelines because of available methods (eg. Project No.)

- Specification of desired date and later actual date

- Responsible person

- Individual text, special user fields like type series, state of development

- Origin of EC, e.g. applying cost center, buisness partner, customer request with specification about complaint no. and date

The EC traverses several states:

- EC established

- In evaluation

- Released for realization

- Refused and closed

- In preparation

- Implemented and closed

Reasons for an EC may be:

- Customer request

- Enquiry of supplier

- Ecconomisation of production process

- Construction failure etc.

An EC object may be:

- Material, partly finished product, article etc.

- Production plant or plant component for a process

- Gauge type, gauge

- Document etc.

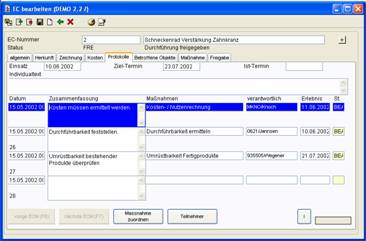

In the mask 'measures' all so far initiated measures belonging to the current EC are listed. The measures are mainly generated during EC sessions. From here further measures can be created immediately.

List of other by the EC affected objects

An EC can refer to one part but affect several other objects. For example a screw with a slightly modified thread profile may have been used for several different mounting processes. By a where-used list in all object lists it is detected if the piece is also used for the assembling of other parts.

If there are changeovers necessary for also affected objects a time presetting will be made (planned/actual date).

The list of affected objects processed during EC sessions and corresponding measures will be generated.

Cost / benefit analysise

- Gathering of all costs for EC implementation ordered by cost type

- Individual remark for each cost entry

- Total costs

- Analogous gathering of all benefits in the same way

- Concluding evaluation of the costs/benefits with description of not rateable advantages and disadvantages

EC session and protocols

- Define kind of session; here ECM

- Issue of meeting

- Date, time and location of meeting

- Inviting person

- Participants, like last meeting or selected from distribution catalogue

- EC to be discussed; normally several in rotative sessions

- Attaching of needed documents for preparation of the session

- Invitation by e-Mail

During the session the EC are shown in a predetermined order.

Overview of all protocols and measures of earlier meetings, entering of the session result.

- Add further measures resulting from actual decisions

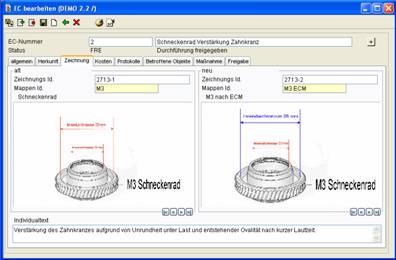

Drawings

- Comparison between old and new drawing; there may be several drawings, pictures etc. in one drawing map

- Individual text for further explanations

- Attaching of all additionally decided measures

Release and notice

- Distinction between release repectively notice during evaluation and preparation

- Description of the release step

- Planned/actual date of release/notice; notices that are not timed do not lead to project delay

- Result text, e.g. at refusion

- Preparation not until released evaluation